Load Formers & Automatic Palletizers

WSA (Woosung Autocon), founded in 1980 in South Korea, manufactures an extensive range of state of the art material handling equipment featuring innovative solutions designed to maximize the productivity and efficiency of today’s modern corrugated box plant. Goettsch is proud to supply the WSA line of material handling and conveyor systems to the International Market*.

The Goettsch team understands the investment you have in your facility; our professionals team up with you to recommend the right equipment solution for your application, facility and budget. And, rest assured, we’re always there to provide on-going parts and service support.

WSA has proven solutions for high speed converting lines, from mini-lines to jumbos, top and bottom printers, standard and high board-line presses, platen die cutters, bundle handling, machine infeed and discharge systems and load formers and palletizers for finished product.

Standard Load Former

jpg.jpg)

The WSA Standard Load Former is by far the most well equipped unit in the industry with standard features including Plastic Belt Lift Conveyor for maximum load stability, Color Touch Screen Operator Interface with full bundle line controls, Roller Ball Table, 7-speed load discharge settings, variable load compression, optional Ethernet remote access interface, Allen Bradley PLC, and much more.

Also available with an optional Air Transfer Table, pallet un-stacking device and infeed delivery system.

- 1500 x 1500mm

- 1500 x 1800mm

- 1800 x 1800mm

- 1800 x 2100mm

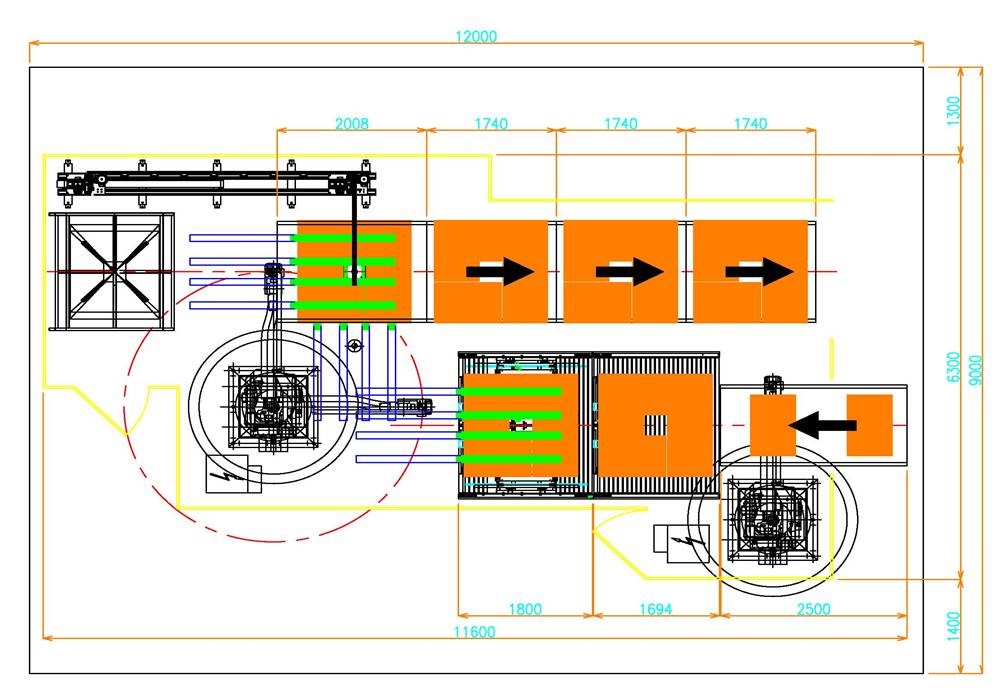

High Speed Load Former

The WSA Tri-Zone High Speed Load Former was designed specifically for the latest high speed flexo folder gluers, running at speeds of up to 400 boxes per minute. The unique design minimizes all cycle times over a conventional load former and allows for the fastest load discharge times in the industry. Maximum sustained running speeds can be achieved even when running a one up or one by two bundle stacking pattern.

The Tri-Zone Load Former features all plastic belt transfer conveyor for maximum load stability, a user friendly touch screen operator interface with full bundle line controls and an air transfer table.

This model can also be equipped with an optional pallet un-stacking and infeed delivery system.

Contact Goettsch International to learn how to maximize the productivity of your new Flexo Folder Gluer with the WSA High Speed Load Former solution.

- 1500 x 1800mm

- 1800 x 1800mm

- 1800 x 2100mm

- maximum stack heights up to 2300mm

Some of the standard features of the WSA Fully Automatic Palletizer are:

- In-line or Right angle configuration

- High Speed Bundle Rotator and Bundle Side Positioning

- Tier/Layer Doubler

- Automatic Pallet or Bottom Sheet Insert

- Automatic Tie Sheet Insert System

- Stack re-squaring system

- Ethernet for Remote Support

- Allen Bradley (or Siemens) PLC

- SICK Safety Sensors

- Large Color Touch Screen Operator Interface

High Speed Robotic Palletizer

The newly launched WSA High Speed Robotic Palletizer represents the next generation in robotic palletizing for today’s very latest High Speed FFG’s and RDC machines.

- Multi Robot solution for faster running speeds and expanded stack patterns

- Each Tier/ Layer is pre-formed by the first robot and then doubled

- Main robot transfers two complete layers in one motion onto the stack

- Independent bottom and tie sheet delivery system

- Faster Cycle Times, Improved stack quality and expanded stack patterns

* Available to specific countries; please consult with Goettsch International for availability.