Partition Equipment

Premier Paper Converting Machinery, Inc. sets the industry standard worldwide for manufacturing the highest quality partition equipment from die cutters to assemblers to collapsers. Premier Paper Converting Machinery (PPCM) has developed machinery solutions to increase production capacities, as well as improve process technology. Goettsch International is proud to offer the complete line of PPCM equipment to the International Market*.

For more than 65 years, Goettsch has been working with large facilities and small shops. We understand the investment you have in your facility. You’ll appreciate the unsurpassed service you receive from Goettsch to recommend the right equipment solution for your application, facility and budget. Then we work closely with our customers to manage the delivery, installation and training, so you can focus on your business. And, we’re always available for on-going parts and service support.

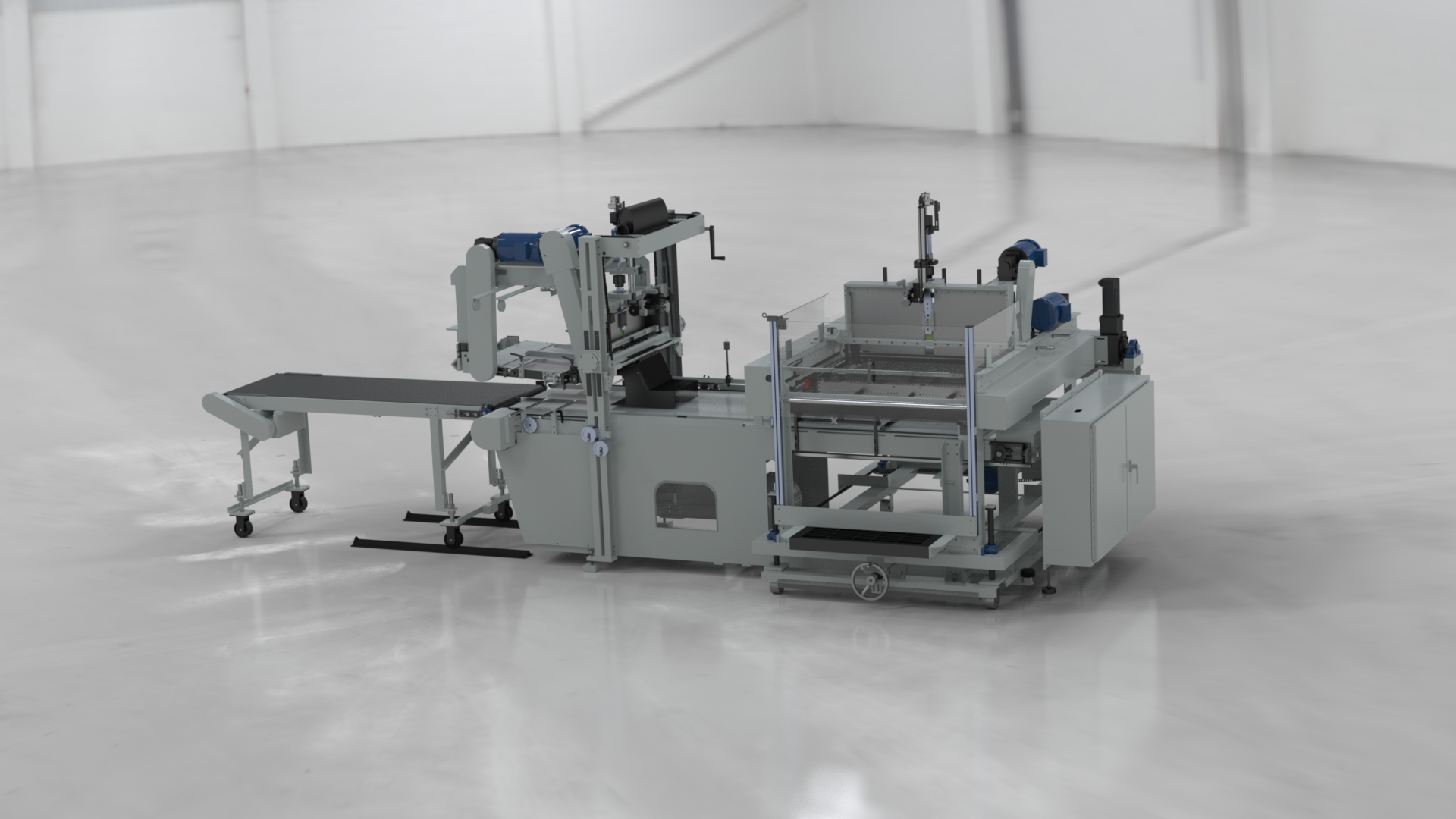

Stripping Machinery

Fiber Stripping:

Premier’s fiber stripping machinery is available to produce clean punch configuration slots and “V” slots simultaneously for ease and speed of assembly. Machinery is available in several width and height capacities to solve your most difficult production needs. This machine also features rapid tool change-over, utilizing top and bottom die set up plates and a shaftless roll rack. This allows for several width capacities, up to 36 inches (91cms), enabling multiple output production requirements for numerous applications.

High Performance:

Premier’s fiber stripper is ergonomically designed for automatic production of fiber partition strips and pads from roll stock. The unique machine design is the basis for high performance and flexibility. High speed precision cuts are assured with servo controls.

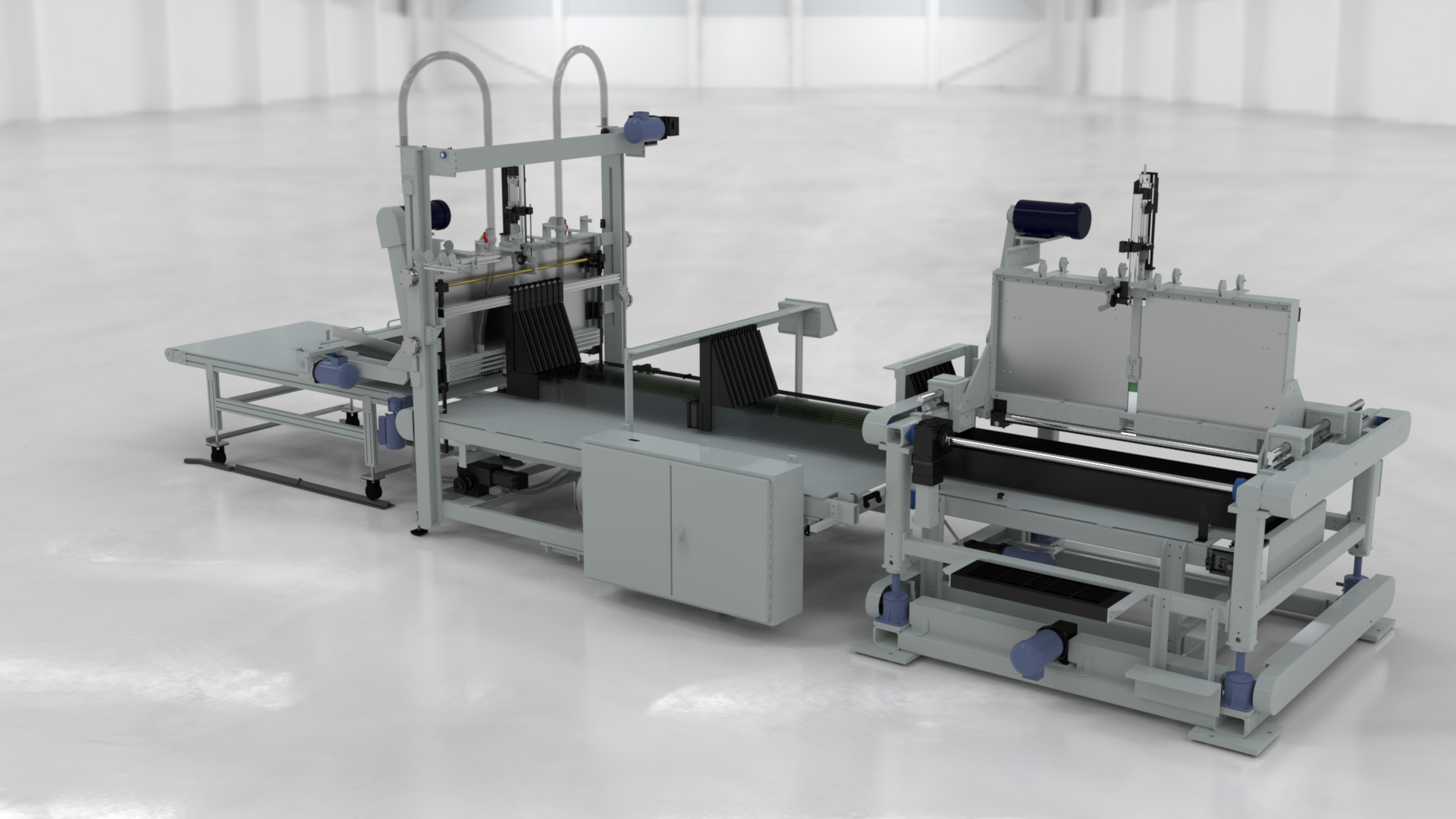

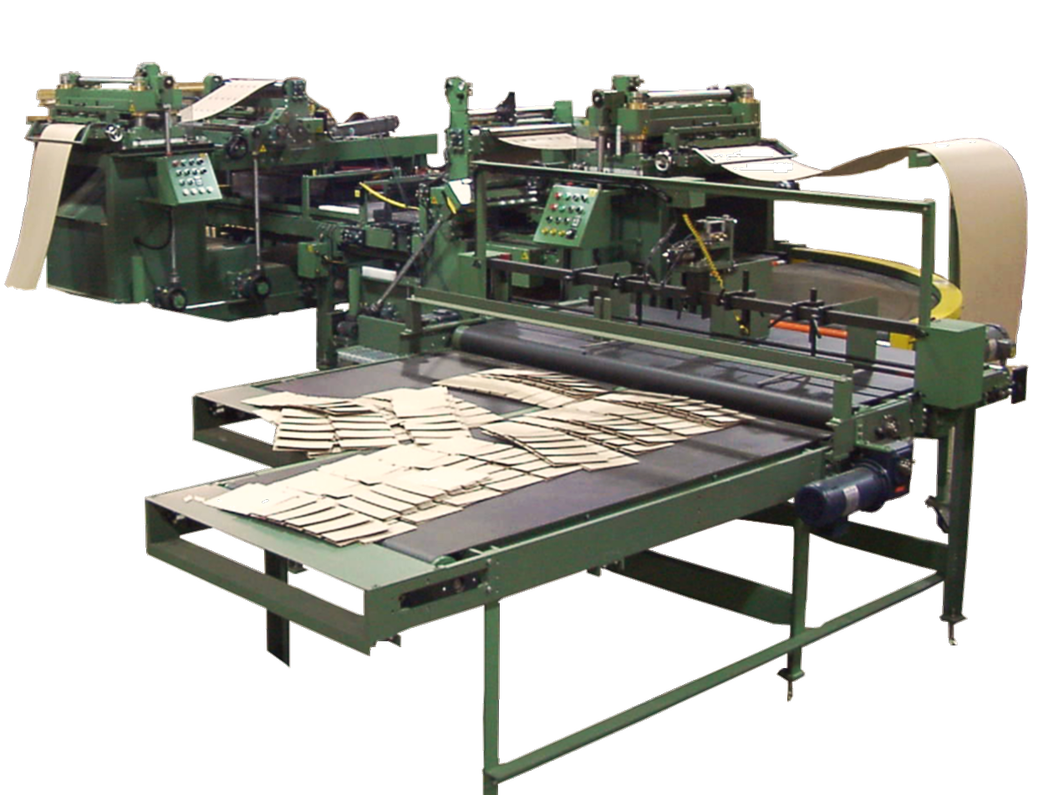

Stripper/Die Cutter

Versatile Stripping Machine:

Different processing operations such as die cutting, slitting, edge trimming and cuttng to length can all be combined into one pass to yield a high output flexible processing center. Die cung machines provide a clean “V” entry slot for fast assembly and various options are available for corner cuts, “V” notching, creasing, scoring and letter piercing. Choose additional options including a tension table and roll rack for manufacturing solid fiber partition strips from roll stock and/ or an additional sheet feeder to eliminate manual feeding operations.

High Volume:

The Corrugated Die Cutting machine is simple to use, highly productive and is designed to increase the value and prolong the life of your machining production investment. Designed primarily for companies needing high volume production of corrugated partition strips and pads as well as multiple configurations.

Assemblers

PPCM assembly machinery is designed to give you the best in high volume production rates for solid fiber and corrugated partitions. Whether it’s standardized products (beer and wine bottles) or versatility you require, Premier has the machinery solution.

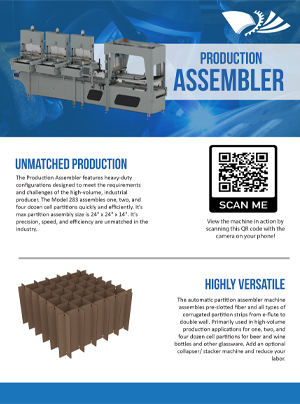

Model 283 Production Assembler

Unmatched Production:

The Production Assembler features heavy-duty configurations designed to meet the requirements and challenges of the high-volume, industrial producer. The Model 283 assembles one, two, and four dozen cell partitions quickly and efficiently. It's max partition assembly size is 24" x 24" x 14". It's precision, speed, and efficiency are unmatched in the industry.

Highly Versatile:

The automatic partition assembler machine assembles pre-slotted fiber and all types of corrugated partition strips from e-flute to double wall. Primarily used in high-volume production applications for one, two, and four dozen cell partitions for beer and wine bottles and other glassware. Add an optional collapser / stacker machine and reduce your labor.

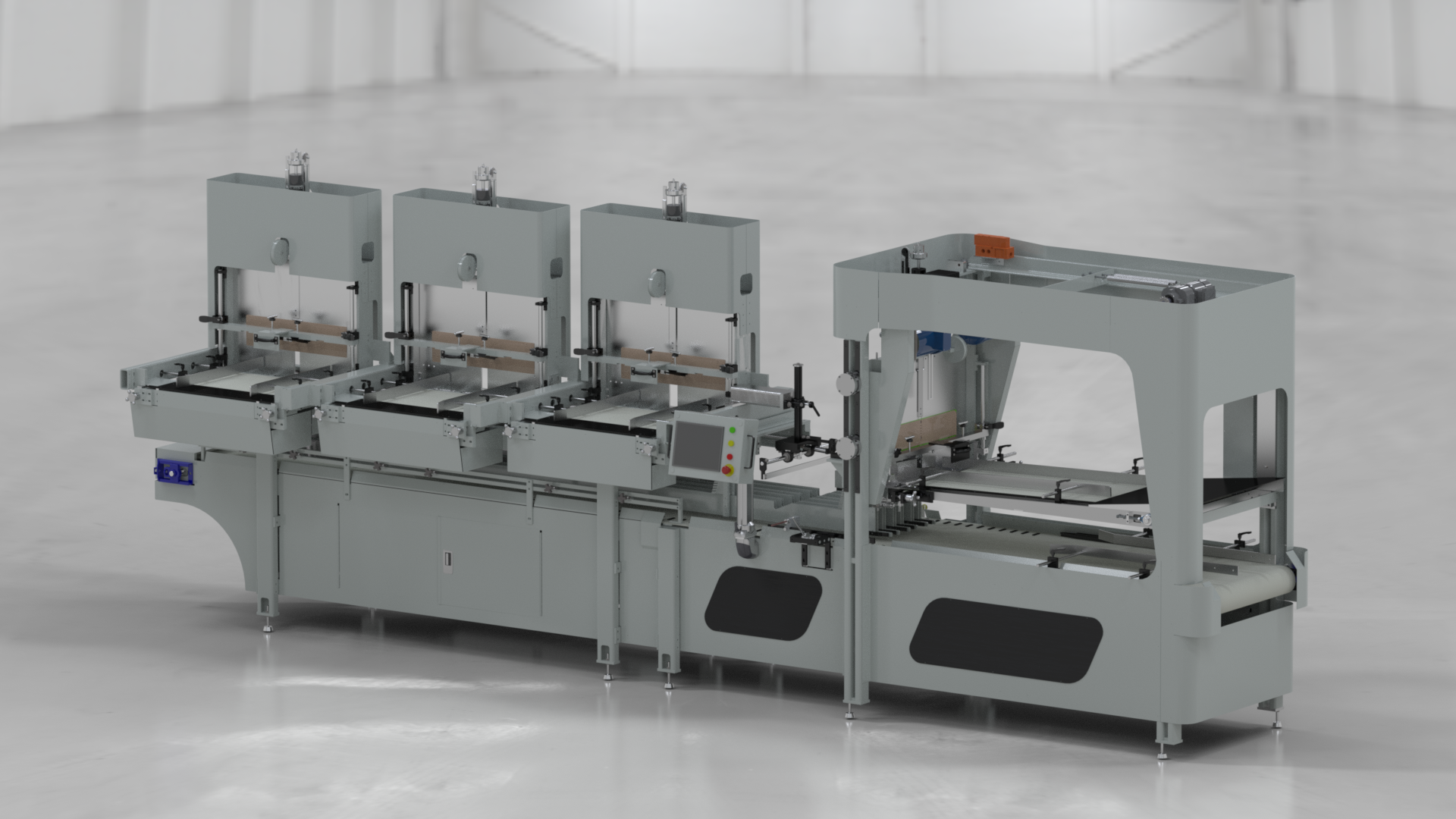

Multi-Cell Assembler

Reliable Production:

The Multi Cell Assembler is an automatic multi-cell partition assembler for pre-slotted fiber or corrugated partition strips. This machine is designed in a standard configuration with eleven feed channels (corrugated) to fourteen feed channels (solid fiber) for true multi-cell capacity. Programmable assembly activation enables even and uneven cell size capabilities and only one switch is required for set-up purposes.

Assembly Machinery:

Our assembly machinery is designed to give you the best in high volume production rates for solid fiber or corrugated partitions. If it's standardized products or versatility you require, Premier has the machinery solution for you.

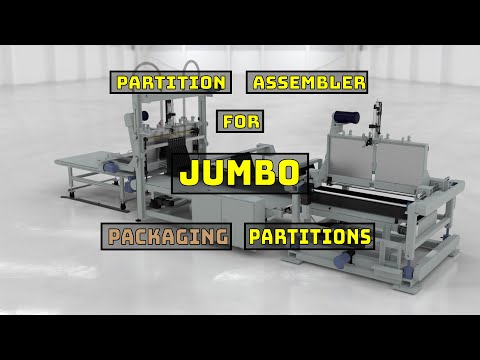

MODEL 221C JUMBO ASSEMBLER

Large Assembly:

Assembling extra-large partitions has never been easier than with Premier’s Jumbo Assembler. By feeding partitions through multiple channels, operators can run and maintain production at a pace exceeding that of multiple employees assembling partitions by hand. The Jumbo Assembler’s servo drives, accessed through its touch-screen panel, gives you the option to ramp up production speed even further, should your project demand it.

Versatile and Customizable:

The Jumbo Assembler, like all of Premier’s machinery, can be customized to fit your organization’s needs. Whether your current production requires hand feed operations, or our auto feeder, Premier has you covered. Our assembly machinery is also extremely versatile and can assemble both corrugated and solid fiber partitions.

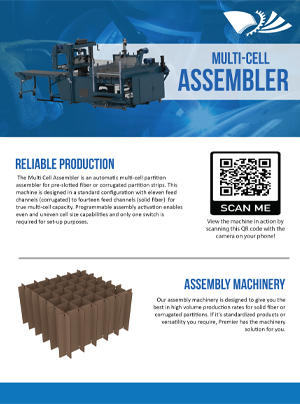

MODEL 263 FULLY AUTOMATIC

Ultimate Solid Fiber Assembler:

Premier’s Fully Automatic Partition Assembler fabricates and assembles box partitions from two fiber chip board rolls. A single operator designates partition specifications on a touch screen, and from there the machine will cut and assemble solid fiber partitions to those specifications. If you are looking to increase automation in your organization, this is the machine you are looking for.

Automated Production:

The Feeder Secon produces die cut partition strips and inserts them into channels which are conveyed to the assembly section. At the Assembly Section, a paper web with pre-cut slots is automatically inserted into partition strips to fabricate an assembled partition. Finally, the Collapsing Section collapses and batches the assembled partitions into sets.

Collapser

.png)

Streamlining the production line to collapse and batch the assembled partitions, keeps this a one operator function and optimizes productivity and profitability.

* Available to specific countries; please consult with Goettsch International for availability.