Shredders - tires

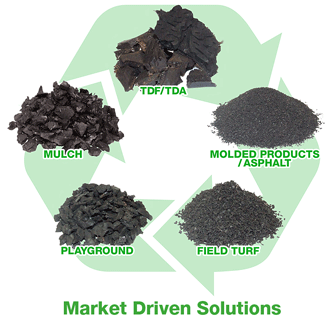

Solutions to Turn End-of-Life Tires into Profits

Columbus McKinnon Corporation, Tire Recycling Equipment Division has been manufacturing tire shredders and tire processing equipment designed to process steel-belted passenger and truck tires for the tire recycling industry since 1982. Goettsch is proud to supply Columbus McKinnon (CM) tire recycling equipment to the International Market*. CM has become a recognized leader for the highest production, best tire chip quality and lowest operating costs in the industry.

For more than 65 years, Goettsch has been working with large facilities and small shops. We understand the investment you have in your facility. You’ll appreciate the unsurpassed service you receive from Goettsch to select the right equipment solution for your application facility and budget. Then we work closely with our customers to manage the delivery, installation and training, so you can focus on your business. And, we’re always available for on-going parts and service support.

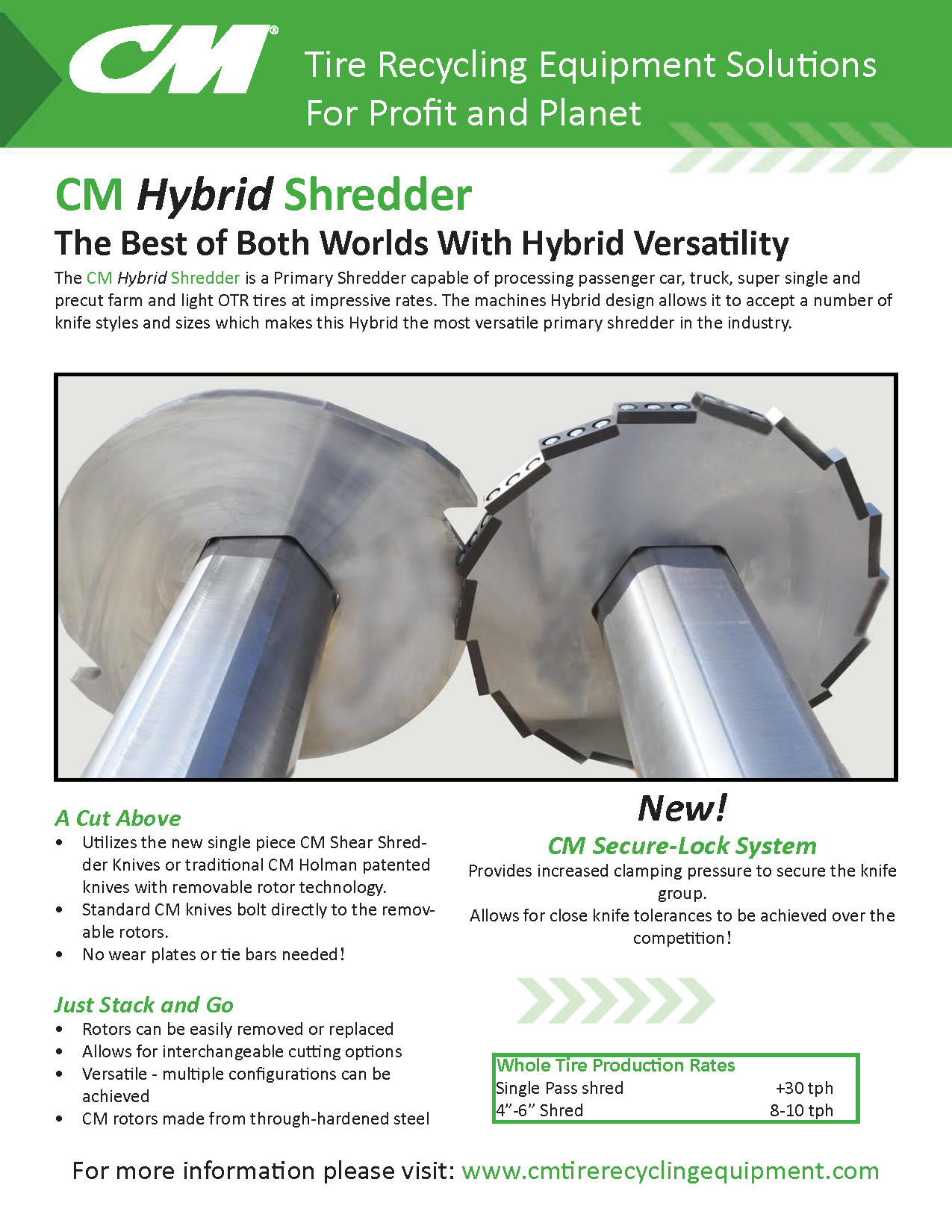

CM Hybrid Primary Shredder

.jpg)

The CM Hybrid Shredder is a Primary Shredder capable of processing passenger car, truck, super single and precut farm and light OTR tires at impressive rates. The machine’s Hybrid design allows it to accept a number of knife styles and sizes which makes this Hybrid the most versatile primary shredder in the industry.

Single pass shred +30 tph

4” – 6” shred 8 – 10 tph

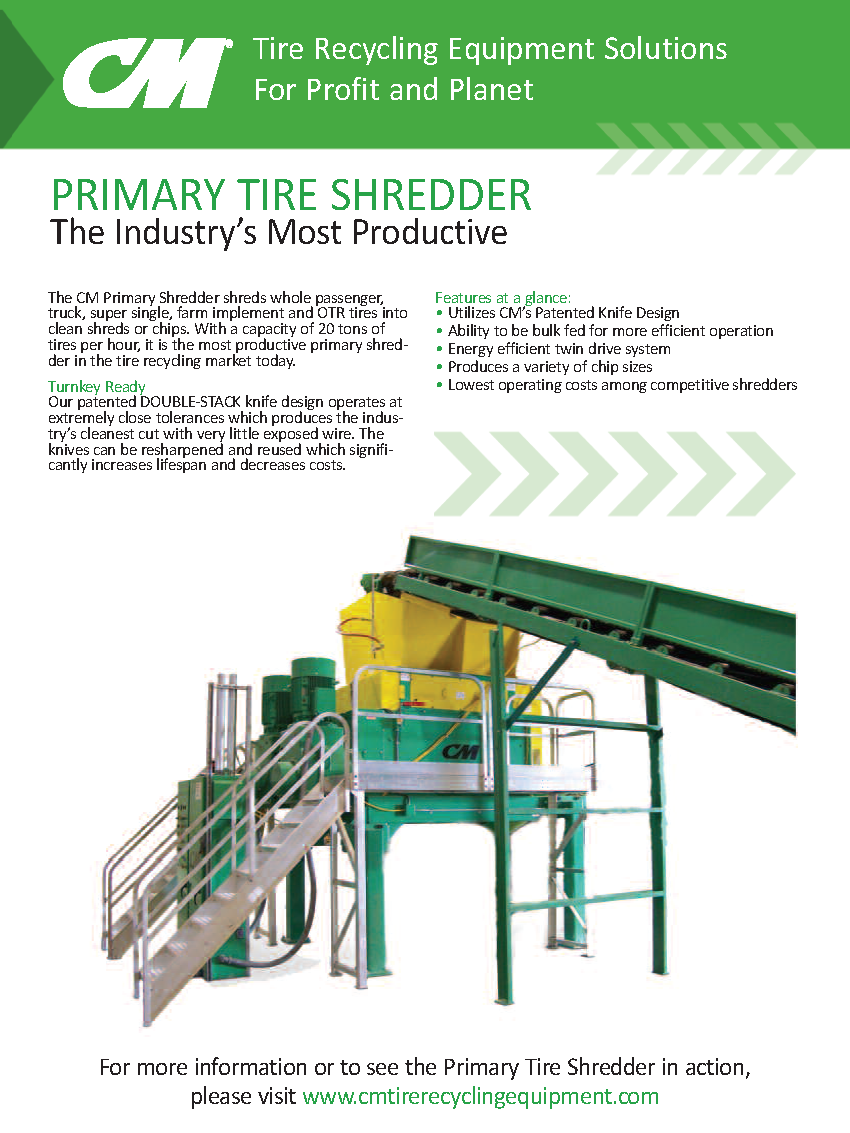

CM Primary Shredder

The CM Primary Shredder shreds whole passenger, truck, super single, farm implement and OTR tires into clean shreds or chips. With a capacity of 20 tons of tires per hour, it is the most productive primary shredder in the tire recycling market today.

CM Dual Drive Single Speed Shredder

The CM Single Speed Tire Shredder is specifically designed to process whole steel belted radial passenger and SUV tires into specifically sized chips. Able to process up to 900 passenger tires per hour, including steel-belted radials.

The shredded chips can be used as feed stock for further processing or be utilized for tire derived fuel (TDF) or tire derived aggregate (TDA).

CM Single Drive Chip Shredder

The CM Single Drive Chip Shredder is a secondary shredder that can accept pre-shredded material from a primary shredder or it can be integrated into a system to produce the recycling industry’s cleanest cut chips. Its proven technology processes up to 10 tons of pre-shredded tire material every hour.

CM Dual Drive Chip Shredder

The CM Dual Drive Chip Shredder can work independently to process whole passenger car, light truck and SUV tires, or as a secondary shredder integrated with other systems to produce the recycling industry’s cleanest cut chips. Its proven technology processes up to 15 tons of pre-shredded tire material every hour.

CM External Classifier

The CM Classifier’s unique design creates a more efficient classification of tire chips/shreds in a compact area. Oversized material is re-circulated to the shredder repeatedly until they are cut to the proper size.

CM2R Liberator

The CM2R Liberator’s patented design allows it to separate the wire from rubber tires in the purest, cleanest form possible, allowing processors to generate revenue streams from both rubber and wire. Due to the enormous success of the larger CM4R Liberator, this new, smaller, more affordable version has been developed by CM to meet the growing demands of the tire recycling market.

CM4R Liberator

The larger capacity CM4R Liberator’s unique design allows it to separate the wire from rubber tires in the purest, cleanest form possible, allowing processors to generate revenue streams from both rubber and wire. This machine boasts double the capacity of the CM2R model.

CM Steel Reclaim System

The CM Steel Reclaim System screens and separates comingled steel and rubber that are generated from the tire recycling process. The material value can be greatly enhanced by this additional processing. The system utilizes a special screen in combination with magnetic separators to reclaim the steel and rubber.

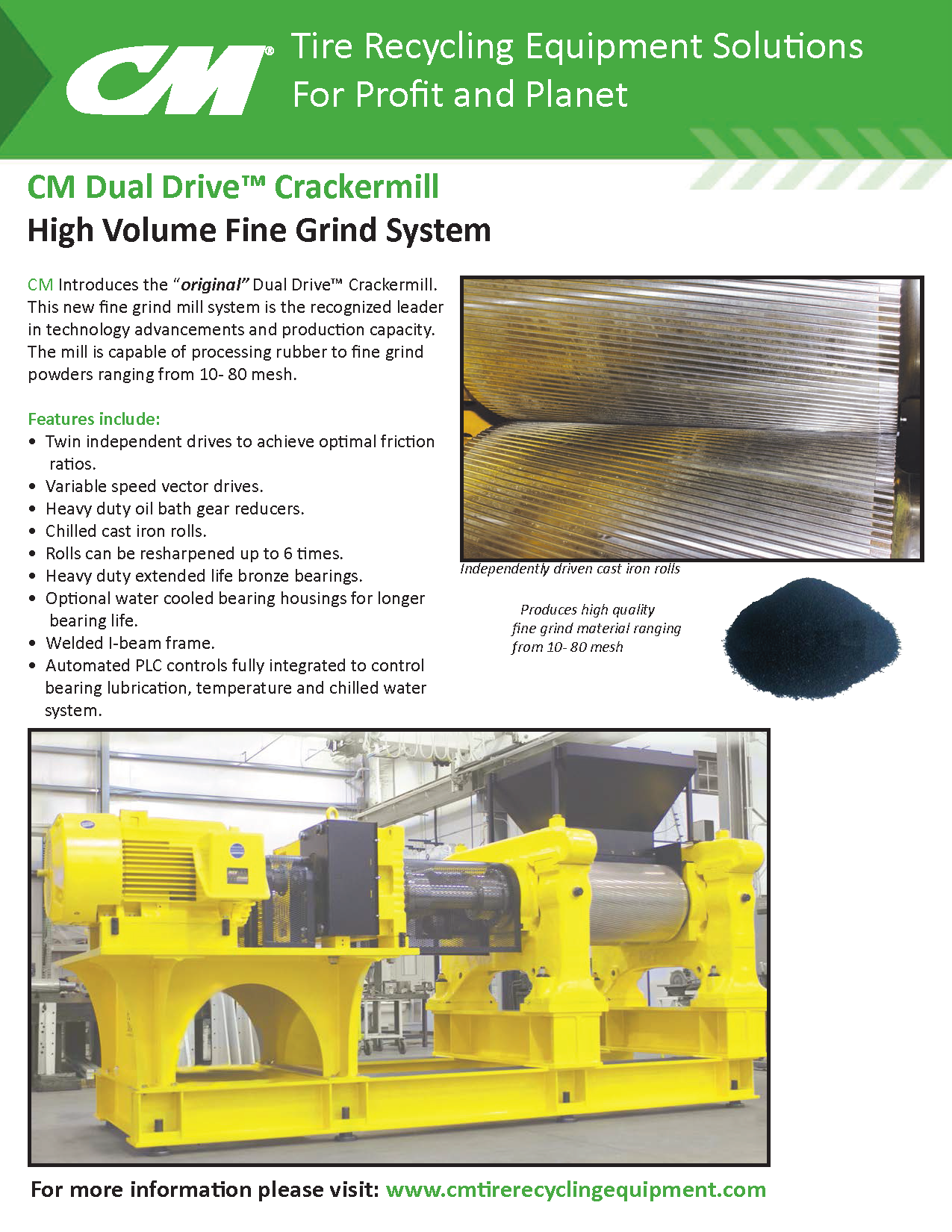

CM Dual Drive™ Crackermill

The Dual Drive™ Crackermill is a fine grind mill system and is the recognized leader in technology advancements and production capacity. The mill is capable of processing rubber to fine grind powders ranging from 10 – 80 mesh.

*Available to specific countries; please consult with Goettsch International for availability.