Other Retrofit Units

SUN Automation Group® has become the industry authority for feeding, printing, and converting technologies and one of the most respected equipment and development companies serving a massive global industry. Goettsch is proud to supply the Sun Automation Group’s line of products to the International Market*.

With the Goettsch team’s unsurpassed service, we find the right equipment solution for your application, facility and budget, create efficiencies and provide on-going parts and service support.

Spectrum® Print Unit

Increase your business opportunities while reducing your operating costs by adding an additional print section to your existing press. When you’re ready to add another print station to your existing finishing line, Sun’s Spectrum Print Station can provide the additional color station for substantial savings!

Two pass printing is expensive and cannot duplicate the quality of a single pass.

- Specific to the machine

- Chambered, single blade, roll-to-roll

- Available to retrofit on many machine manufacturers and models

- Unsurpassed registration – SunTrac® Vacuum Transfer increases accuracy of close register work

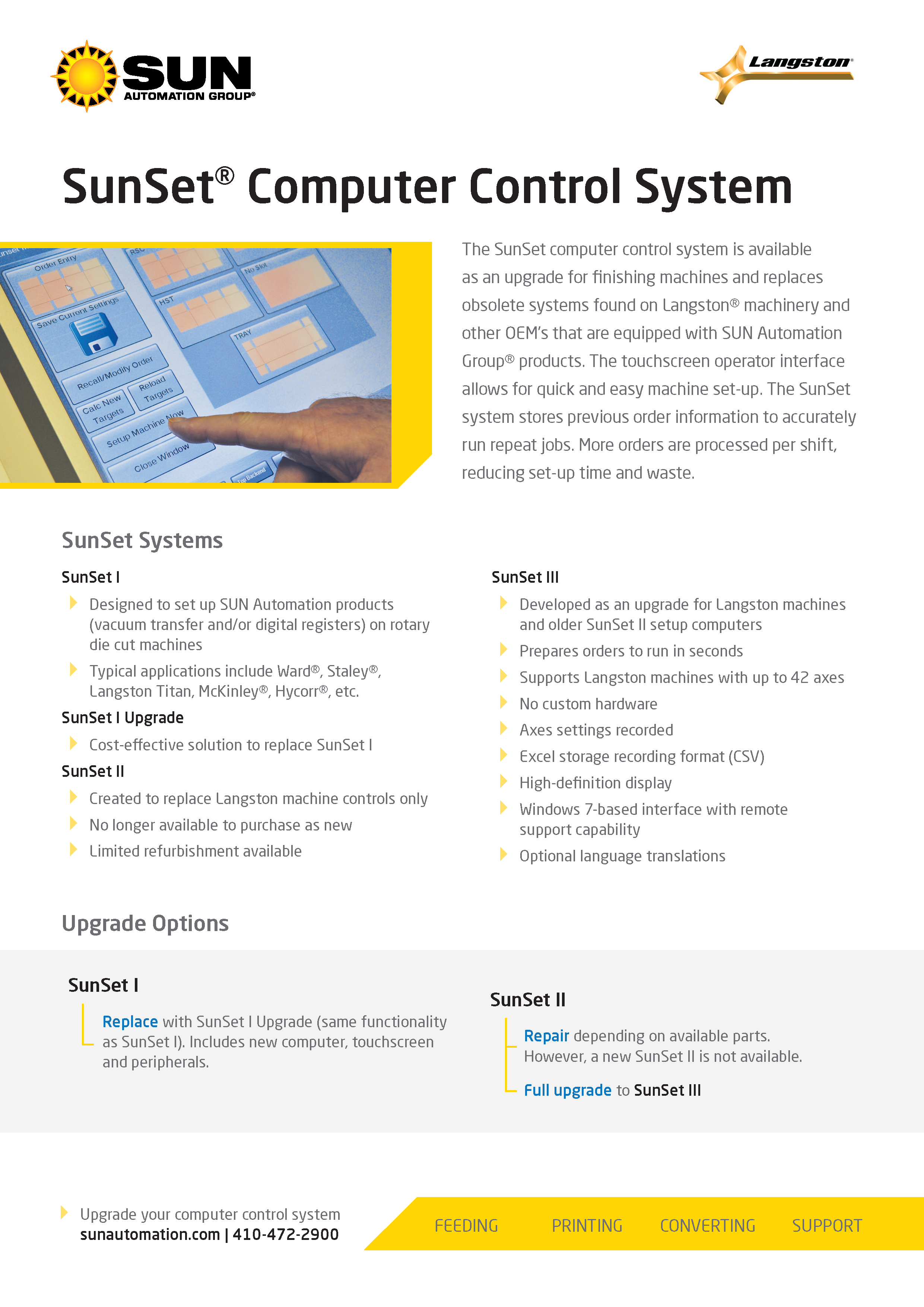

SunSet® Computer Control System

The computer control system is the state-of-the-art computerized set-up control for a finishing machine. The touch-screen operator interface allows for easy and quick machine set-up. The SunSet computer control system stores previous order information to accurately run repeat jobs. Touch-screen allows for setting box dimensions directly on a graphic of the box; no keyboard entry is required.

| If you currently have a SunSet I |

If you currently have a SunSet II |

No current computer system

(equipped with Sun Automation vacuum transfer and/or digital register)

|

Replace with SunSet I Upgrade (same functionality as SunSet I). Includes new computer, Touchscreen and peripherals, OR

|

Repair depending on available parts. However, a new SunSet II is no longer available, OR |

Install SunSet III, the improved and current Sun Automation setup computer |

| Full upgrade to SunSet III |

Full upgrade to SunSet III |

|

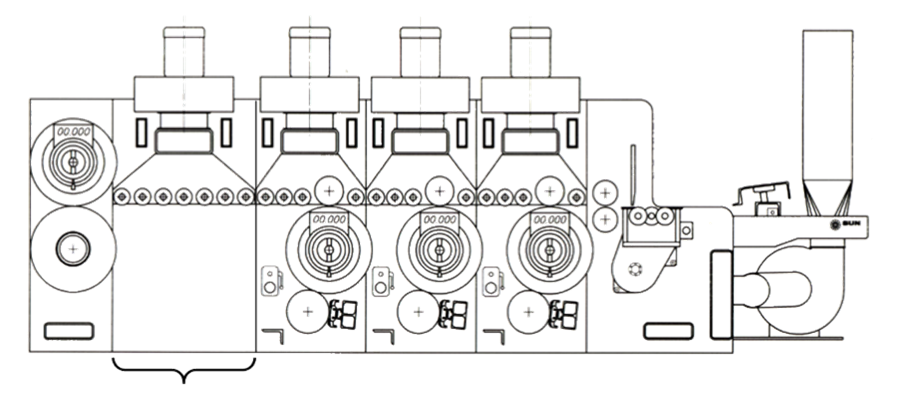

Dwell Unit

The Vacuum Transfer Dwell Unit usually fits between the last print unit and the die cut unit to ensure printing is completed before die cutting begins. It also provides additional ink drying time and space for drying units.

The fundamental advantage of a dwell unit is to ensure two functions are not engaged with a single corrugated sheet at one time.

- Improve print quality

- Improve production speed

- Eliminate print smearing that occurs in the die cutter by increasing the dwell time and ensuring the sheet is free from the last print plate nip

PrintPrep® Sheet Cleaner

Sun’s PrintPrep® unit is an in-line sheet cleaner that can be adapted to existing finishing equipment. The unit cleans sheets by utilizing a de-ionizing static bar to neutralize the electrical charge that binds dust particles to the liner and a rotating non-static brush to sweep them away. PrintPrep is equipped withSunTrac® vacuum transfer system to ensure accurate sheet transfer.

Machine downtime for plate cleaning is dramatically reduced because dust is not transferred from the substrate to the printing plates.

An optional magnetic bar is available to remove metallic particles from the board that come from sharpening mechanisms to avoid anilox roll damage.

PrintPrep is engineered to be compatible with many OEM machine manufacturers and models.

Feed Table Backstop

The purpose of the Feed Table Backstop is to provide a convenient place for operators to stack sheets from hopper while clearing feeder or pre-feeder jams. This reduces the risk of tripping as well as back and other potential injuries when removing sheets (especially large) from hopper.

Typically, people place a corrugated pile on the ground or to the side as there was no suitable place to set a board aside when working on a machine. The Feed Table Backstop provides a simple, yet effective alternative that saves time and increases convenience.

Spectrum Inside Print

Color Units for a Variety of Makes & Models

Internal printing expands on branding and messaging! SUN Automation’s innovative printing solutions can be retrofitted to most machines, permitting graphics on the inside of the box.

- SunTrac Vacuum Transfer system for accurate sheet control

- Specific board caliper settings within .001” (.025 mm)

- Harmonic Drive digital register allows maintenance free operation

- ColorMaster blade system controls precise ink metering

- Self-contained controls for easy installation and maintenance

- Additional Track Extension available

* Available to specific countries; please consult with Goettsch International for availability.