Flexo Folder Gluers

Dong Fang, the leading manufacturer of Rotary Die Cutters, Flexo Folder Gluers and Flexo Printer Slotters of corrugated in China. The quality and standards of Dong Fang are recognized worldwide. Goettsch is proud to supply the Dong Fang line of products to the International Market*.

Goettsch understands the investment you have in your facility; let our professionals team up with you to provide the right equipment solution for your application and facility. And, rest assured, we’re always there to provide on-going parts and service support.

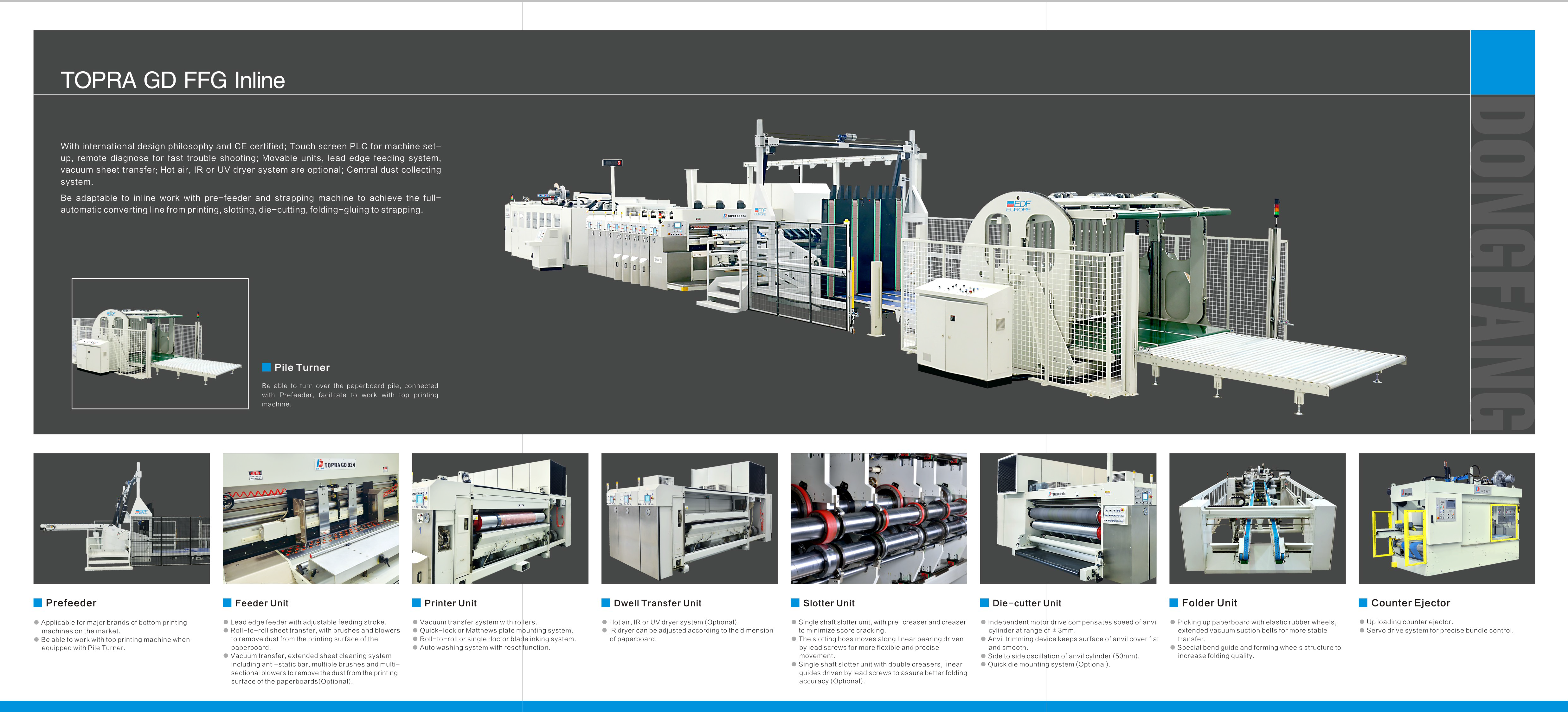

Topra GD Flexo Folder Gluer (Top Printing)

).jpg)

The Topra GD is a Hi-Graphics Precision Inline Flexo Folder Gluer featuring top printing, movable units, lead edge feeding system, servo drive and vacuum transfer. Touch screen PLC for frequent order recall and easy set-up and central dust collecting system.

Available in various feeding sizes from 900mm to 1600mm X 2000mm to 3200mm.

The Topra GD Flexo Folder Gluer includes:

- Sun Automation Group’s Extend-O-Feed, Four Shaft Lead Edge Feeder

- Variable frequency drive control of vacuum suction and pressure to match different size paperboard

- Extended sheet cleaning system

- Single doctor blade or roll-to-roll inking system

- Auto washing system included with ‘wash-while-run’ capability for fast, efficient ink cleanup

- Single shaft slotter unit (optional is double shaft unit)

- Pre-creaser and creaser to minimize score cracking and promote better folding accuracy

- Precision servo folding section

- Positive gap and fishtail control

- Top loading servo counter ejector

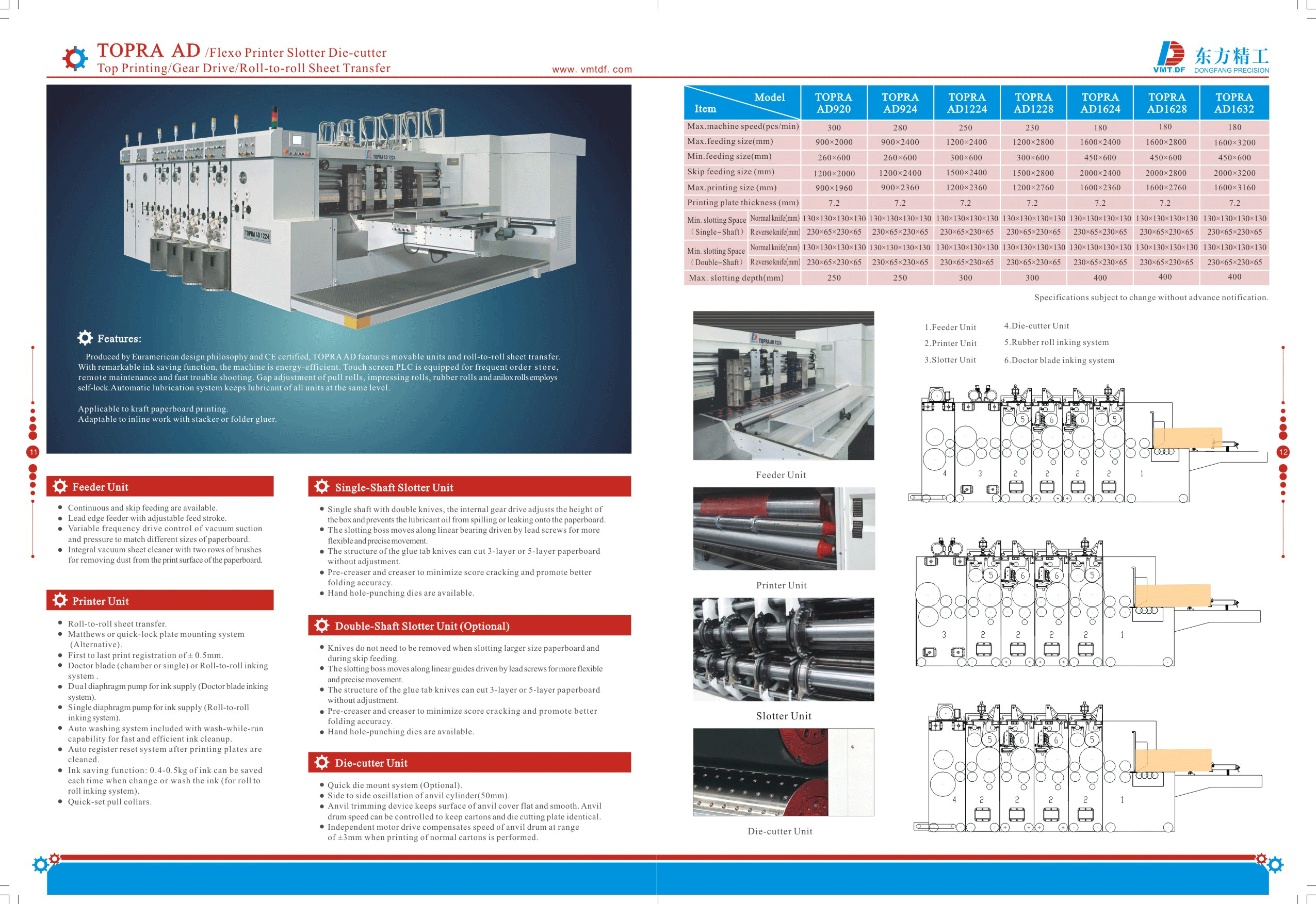

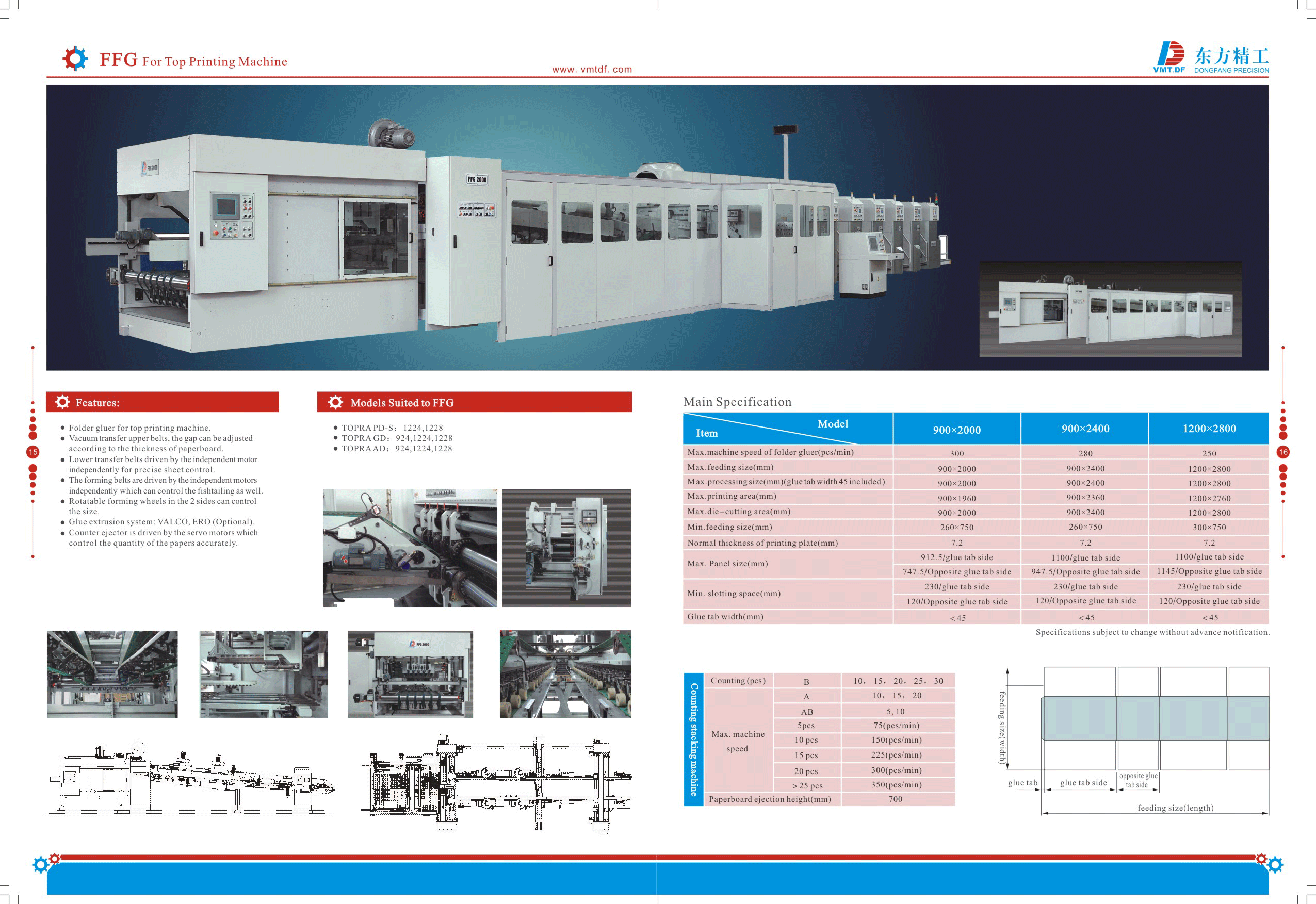

Topra AD Flexo Folder Gluer (Top Printing)

).jpg)

The Topra AD Flexo Folder Gluer features top printing, gear drive and roll-to-roll sheet transfer. It also features movable units, touch screen PLC for frequent order recall, gap adjustment of pull rolls, impression rolls and anilox rolls employ self-lock. Ideal for kraft paperboard printing.

Available in various feeding sizes from 900mm to 1600mm X 2000mm to 3200mm.

The Topra AD Flexo Folder Gluer includes:

- Sun Automation Group’s Extend-O-Feed, Four Shaft Lead Edge Feeder

- Variable frequency drive control of vacuum suction and pressure to match different size paperboard

- Vacuum sheet cleaning system

- Roll-to-roll sheet transfer

- Chambered or single doctor blade or roll-to-roll inking system

- Auto washing system included with ‘wash-while-run’ capability for fast, efficient ink cleanup

- Quick-set pull collars

- Single shaft slotter unit with double knives (optional is double shaft unit)

- Pre-creaser and creaser to minimize score cracking and promote better folding accuracy

- Vacuum transfer upper belts

- Lower transfer belts driven independently for precise sheet control

- Servo motor counter ejector

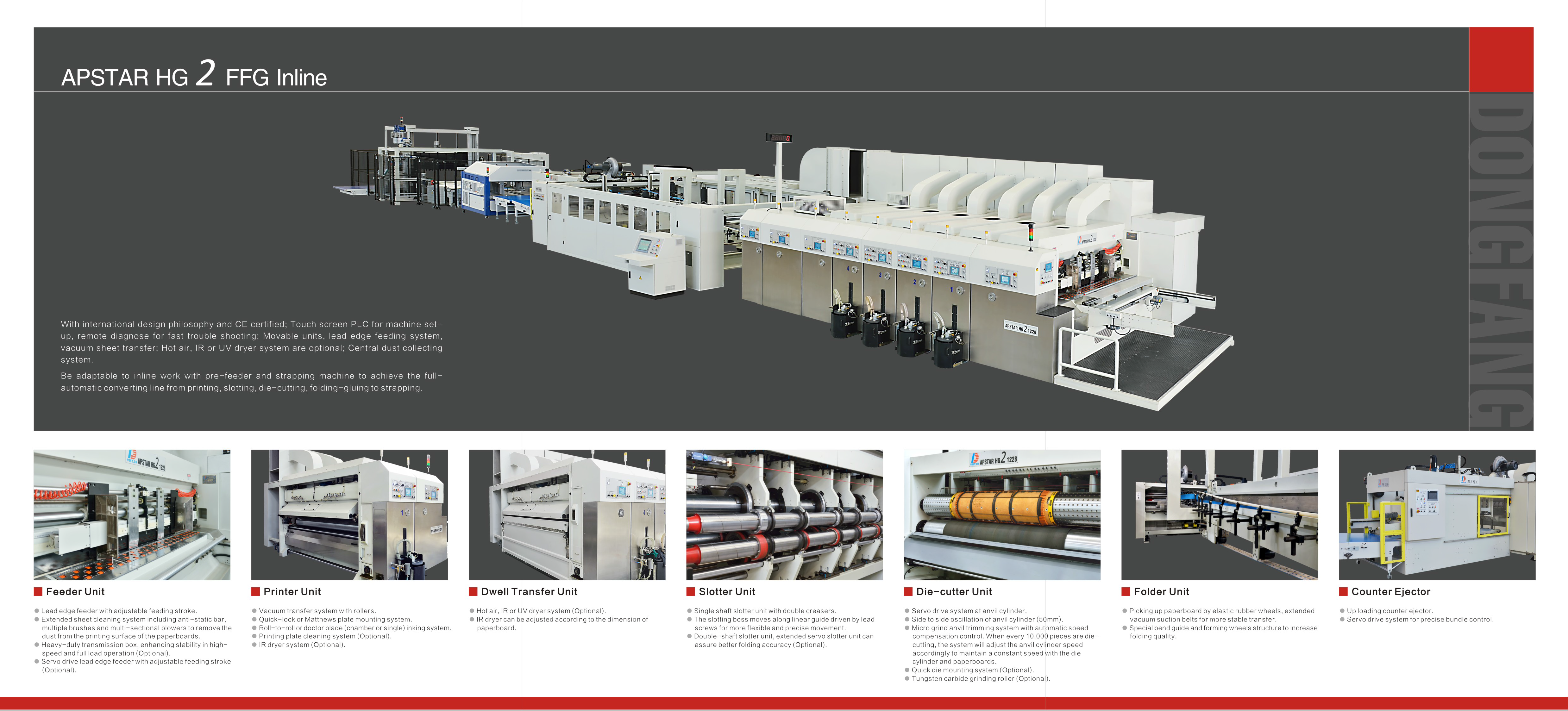

Apstar HG2 Flexo Folder Gluer (Bottom Printing)

The Apstar HG2 FFG is a world-class machine that includes more standard features than any other brand on the market today! Intelligent design and smooth linear processes maximizes production speeds, minimizes labor and achieves the best ROI for corrugated packaging plants.

The Apstar HG2 FFG Inline includes:

- Touch screen PLC’s with Operator Control Console for easy set-up

- Movable units

- Sun Automation Group’s Extend-O-Feed, Four Shaft Lead Edge Feeder with adjustable feeding stroke

- Extended Sheet Cleaning System

- Central dust collecting system

- Vacuum Transfer Print Units with Roll-to-Roll or Doctor Blade (chamber or single) inking system

- Dwell Transfer Unit

- Single shaft slotter unit with double creasers

- Rotary Die Cut Section with Sun Automation MicroGrind full width grinding roll

- Folder unit with extended vacuum suction belts for more stable transfer

- Up loading counter ejector with servo drive for precise bundle control

-

Sheets can be delivered from the corrugator line without reversing the stack directly to the RDC.

- Inking system is below the paperboard line; no ink contamination on the sheets, easier to clean

- Easier to clean die cutting waste

- Bottom printing RDC is the most typical and popular converting machines in the American and European markets

*Available in specific countries; please consult with Goettsch International for availability