Prefeeders

WSA (Woosung Autocon), founded in 1980 in South Korea, manufactures an extensive range of state of the art material handling equipment featuring innovative solutions designed to maximize the productivity and efficiency of today’s modern corrugated box plant. Goettsch is proud to supply the WSA line of material handling and conveyor systems to the International Market*.

For more than 65 years, Goettsch has been working with large facilities and small shops. We understand the investment you have in your facility. You’ll appreciate the unsurpassed service you receive from Goettsch to recommend the right equipment solution for your application, facility and budget. Then we work closely with our customers to manage the delivery, installation and training, so you can focus on your business. And, we’re always available for on-going parts and service support.

WSA has proven solutions for high speed converting lines, from mini-lines to jumbos, top and bottom printers, standard and high board-line presses, platen die cutters, bundle handling, machine infeed and discharge systems and load formers, palletizers and pallet insert systems for finished loads.

Top Print Prefeeders

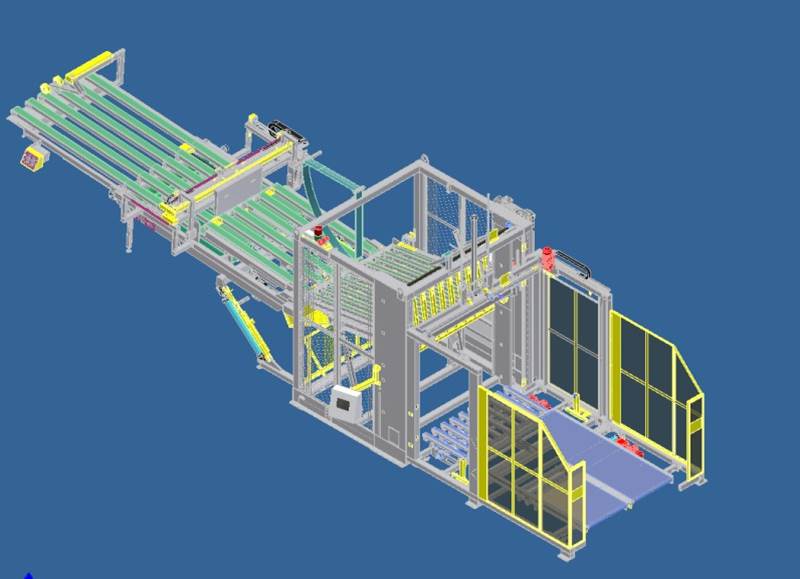

Automatic Overturn Top Prefeeder

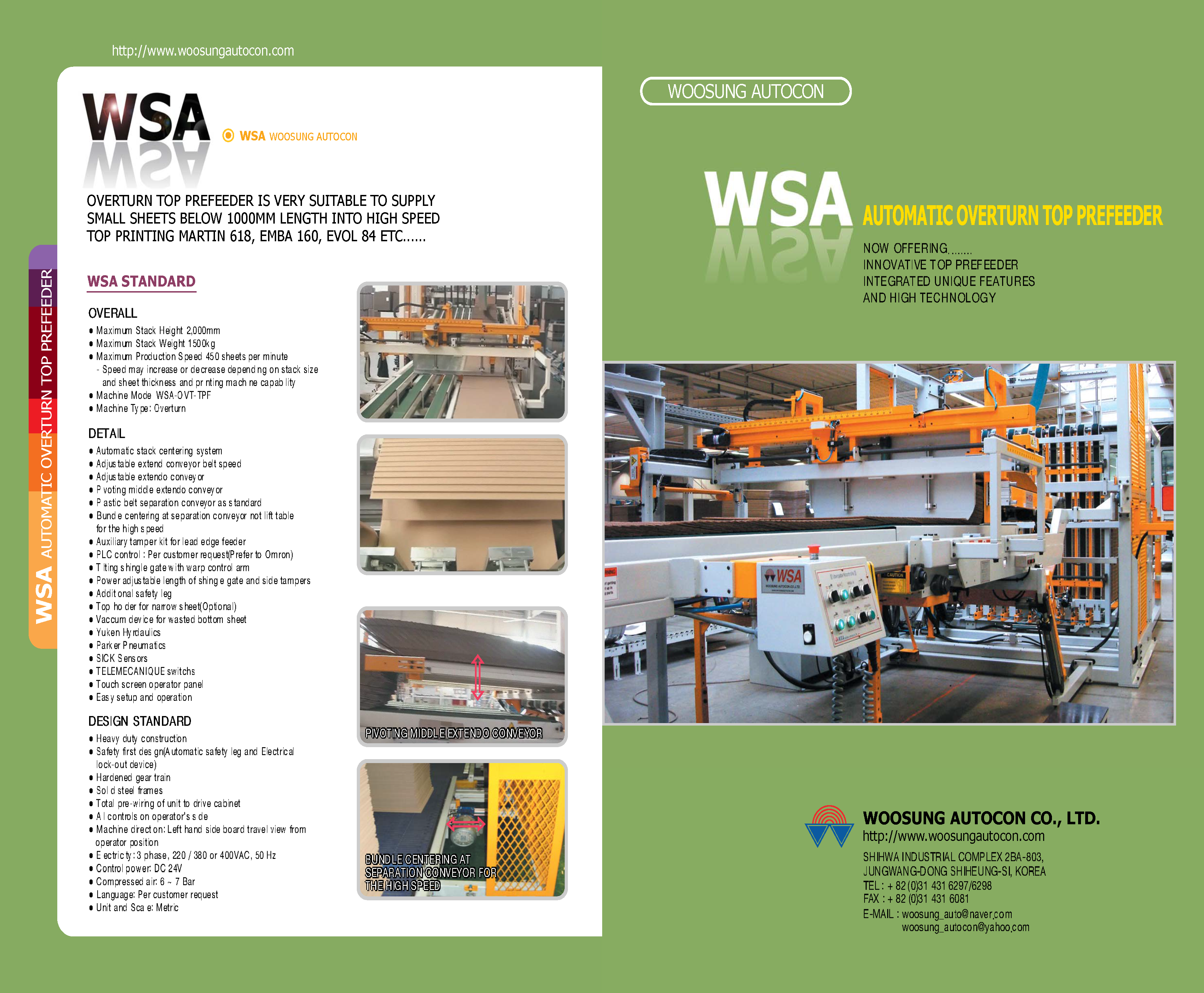

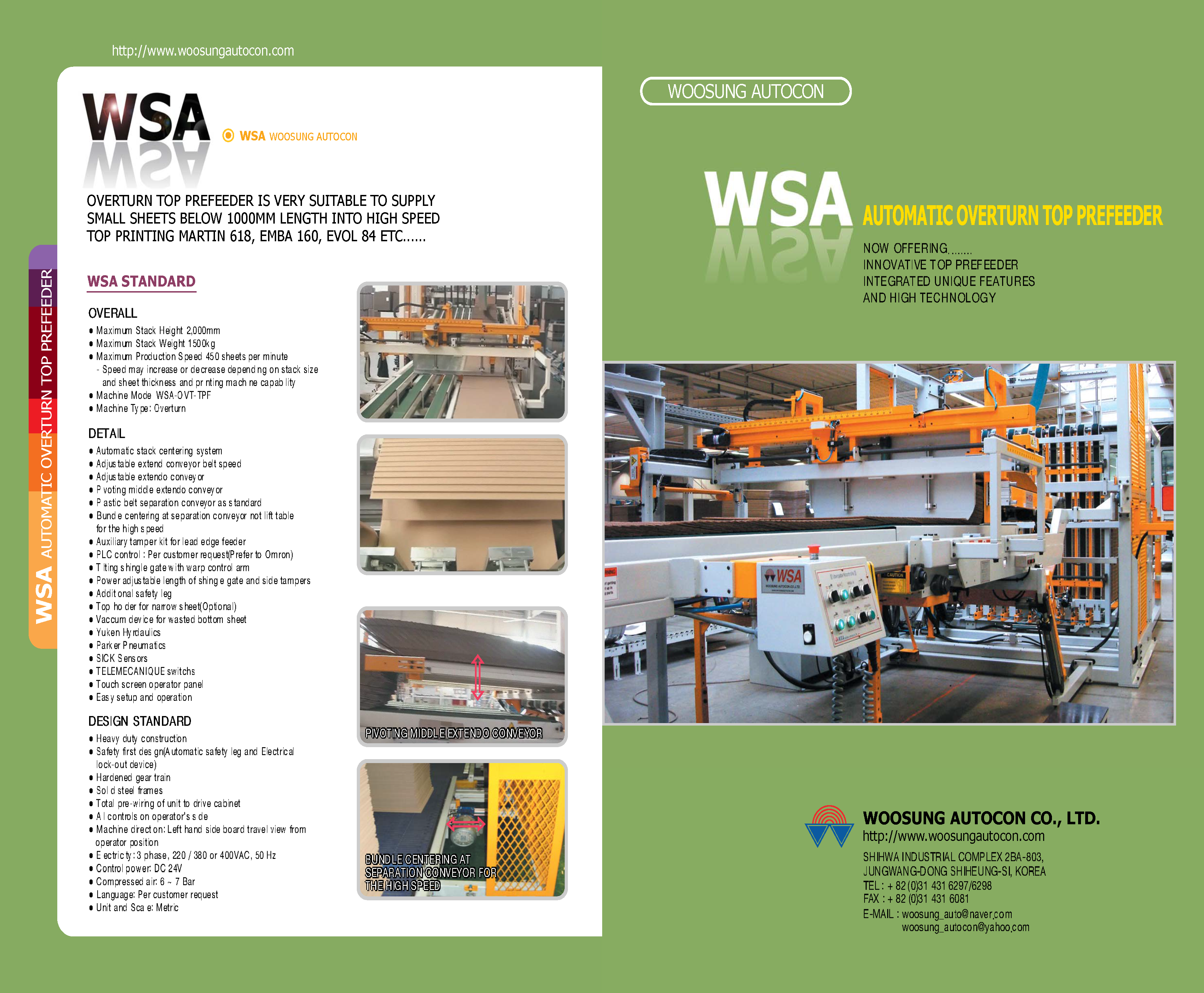

The WSA Top Print Overturn Prefeeder is designed for today’s most advanced top printing Mini-line and Mid-Size Flexo Folder Gluers that run at speeds of up to 450 sheets per minute and features very quick setups. This model inverts the entire stack in one motion, advances the stack onto an extendo conveyor and into a pre-hopper, then delivers a continuous shingle of board to the press. This design maximizes the amount of board which can be stored on the extendo conveyor and delivers the most consistent stream of board to the press even when handling very small blank sizes.

Some of the standard features of the WSA Top Print Overturn Prefeeder are:

- Auxiliary Stack Separation and Centering Zone with Plastic Belt Infeed Conveyor

- Small Blank Stabilizer Arm for handling very narrow sheets

- Stack Inverter with vacuum control of bottom sheet

- Bottom Sheet Waste Discharge System for only removing the bottom sheet

- Pre-hopper with sheet squaring arms

- Deck Snubbing Wheels for control of sheets entering press hopper

- Hopper Tampers for squaring sheets in hopper

- Fully Automatic Setup interfaced with Press

- Color Touch Screen Operator Interface with complete machine diagnostics

- Automatic Bottom Sheet Waste Discharge

- Allen Bradley (or Omron) PLC

- SICK Safety Sensors

- All name brand and commercially available components

Automatic Top Prefeeder with Dual Inverter

The WSA Top Print Dual Inverter Prefeeder features a unique dual block inverter system which minimizes cycle time. This model is designed for midsize and larger high speed top print flexo folder gluers which run up to 350 sheets per minute.

Some of the standard features of the WSA Top Print Dual Inverter Prefeeder are:

- Auxiliary Stack Separation and Stack Centering Zone with Plastic Belt Infeed Conveyor

- Finger Style Block Pusher for improved handling of warped board

- Block Squaring Arms for re-squaring of sheets before shingle gate

- Deck Snubbing Wheels for control of sheets entering press hopper

- Side and Rear Hopper Tampers for squaring sheets in hopper

- Fully Automatic Setup interfaced with Press

- Color Touch Screen Operator Interface with complete machine diagnostics

- Automatic Bottom Sheet Waste Discharge to Operator Side

- Allen Bradley (or Omron) PLC

- SICK Safety Sensors

- All name brand and commercially available components.

- Optional Air Infusion System for improved handling of E flute

Jumbo Top Print Prefeeder

The WSA Jumbo Top Print Dual Inverter Prefeeder features a unique dual block inverter system which minimizes cycle time with sizes up to 2200mm (86.6 inches) X 5500mm (216.5 inches). This jumbo model is designed for larger high speed top print flexo folder gluers which run up to 200 sheets per minute.

Some of the standard features of the WSA Jumbo Top Print Dual Inverter Prefeeder are:

- Auxiliary Stack Separation and Stack Centering Zone with Plastic Belt Infeed Conveyor

- Finger Style Block Pusher for improved handling of warped board

- Block Squaring Arms for re-squaring of sheets before shingle gate

- Deck Snubbing Wheels for control of sheets entering press hopper

- Side and Rear Hopper Tampers for squaring sheets in hopper

- Fully Automatic Setup interfaced with Press

- Color Touch Screen Operator Interface with complete machine diagnostics

- Automatic Bottom Sheet Waste Discharge to Operator Side

- Allen Bradley (or Omron) PLC

- SICK Safety Sensors

- All name brand and commercially available components

Bottom Print Prefeeders

Standard Bottom Print Prefeeders

.jpg)

The WSA Bottom Print Block Push Prefeeder incorporates many unique and innovative design features to maximize the productivity of today’s high speed bottom print Flexo Folder Gluer and Rotary Die Cutter machines. It is engineered for a maximum press speed of 350 sheets per minute and is proven on all of the latest bottom print converting machines.

Some of the standard features of the WSA Bottom Print Block Push Prefeeder are:

- Auxiliary Stack Separation and Stack Centering Zone with Plastic Belt Infeed Conveyor

- Finger Style Block Pusher for improved handling of warped board

- Auxiliary Block Staging Zone for high speed running of doublewall

- Block Squaring Arms for re-squaring of sheets before shingle gate

- Deck Snubbing Wheels for control of sheets entering press hopper

- Side and Rear Hopper Tampers for squaring sheets in hopper

- Fully Automatic Setup interfaced with Press

- Color Touch Screen Operator Interface with complete machine diagnostics

- Allen Bradley (or Omron) PLC

- SICK Safety Sensors

- All name brand and commercially available components

- Optional Air Infusion System for improved handling of E flute

- Optional Powered Side Discharge of Waste Sheet

- Optional Moveable Prefeeder design for presses with 7 colors and above

Continuous Feed Bottom Print Prefeeder

(continuous).jpg)

The WSA Continuous Feed Bottom Print Block Push Prefeeder incorporates many unique and innovative design features to maximize the productivity of today’s high speed bottom print Flexo Folder Gluer and Rotary Die Cutter machines. This model advances the stack onto an extendo conveyor and into a pre-hopper, then delivers a continuous shingle of board to the press. This design maximizes the amount of board which can be stored on the extendo conveyor and delivers the most consistent stream of board to the press. It is engineered for a maximum press speed of 350 sheets per minute and is proven on all of the latest bottom print converting machines.

Some of the standard features of the WSA Continuous Feed Bottom Print Block Push Prefeeder are:

- Auxiliary Stack Separation and Stack Centering Zone with Plastic Belt Infeed Conveyor

- Finger Style Block Pusher for improved handling of warped board

- Auxiliary Block Staging Zone for high speed running of doublewall

- Block Squaring Arms for re-squaring of sheets before shingle gate

- Deck Snubbing Wheels for control of sheets entering press hopper

- Rear Hopper Tamper for squaring sheets in hopper

- Fully Automatic Setup interfaced with Press

- Color Touch Screen Operator Interface with complete machine diagnostics

- Allen Bradley (or Omron) PLC

- SICK Safety Sensors

- All name brand and commercially available components

- Optional Air Infusion System for improved handling of E flute

- Optional Powered Side Discharge of Waste Sheet

- Optional Moveable Prefeeder design for presses with 7 colors and above

- Optional Hopper Side Tampers

Jumbo Bottom Print Prefeeder

The WSA Jumbo Bottom Print Block Push Prefeeder incorporates many unique and innovative design features to maximize the productivity of today’s high speed bottom print Flexo Folder Gluer and Rotary Die Cutter machines. It is engineered for a maximum press speed of 200 sheets per minute with sizes up to 2200mm (86.6 inches) X 5500mm (216.5 inches), and is proven on all of the latest bottom print converting machines.

Some of the standard features of the WSA Jumbo Bottom Print Block Push Prefeeder are:

- Auxiliary Stack Separation and Stack Centering Zone with Plastic Belt Infeed Conveyor

- Finger Style Block Pusher for improved handling of warped board

- Block Squaring Arms for re-squaring of sheets before shingle gate

- Deck Snubbing Wheels for control of sheets entering press hopper

- Side and Rear Hopper Tampers for squaring sheets in hopper

- Fully Automatic Setup interfaced with Press

- Color Touch Screen Operator Interface with complete machine diagnostics

- Automatic Bottom Sheet Waste Discharge to Operator Side

- Allen Bradley (or Omron) PLC

- SICK Safety Sensors

- All name brand and commercially available components

- Optional Air Infusion System for improved handling of E flute

* Available to specific countries; please consult with Goettsch International for availability.