Viscosity Control

Founded in 1985, InkSpec is recognized worldwide as the most proactive, innovative and knowledgeable manufacturer of high quality viscosity controls for the printing industry. Optimizing your ink viscosity has never been easier! Goettsch International is proud to supply the InkSpec line of corrugated Viscosity Control Systems to the International Market*.

Founded in 1985, InkSpec is recognized worldwide as the most proactive, innovative and knowledgeable manufacturer of high quality viscosity controls for the printing industry. Optimizing your ink viscosity has never been easier! Goettsch International is proud to supply the InkSpec line of corrugated Viscosity Control Systems to the International Market*.

Viscosity instability can result in:

- Color Variations

- Inconsistent Drying Speeds

- Higher Ink Consumption

- Increased Downtime

- Poor Overall Print Quality

The Goettsch team understands the investment you have in your facility; our professionals team up with you to recommend the right equipment solution for your application, facility and budget. And, rest assured, we’re always there to provide on-going parts and service support.

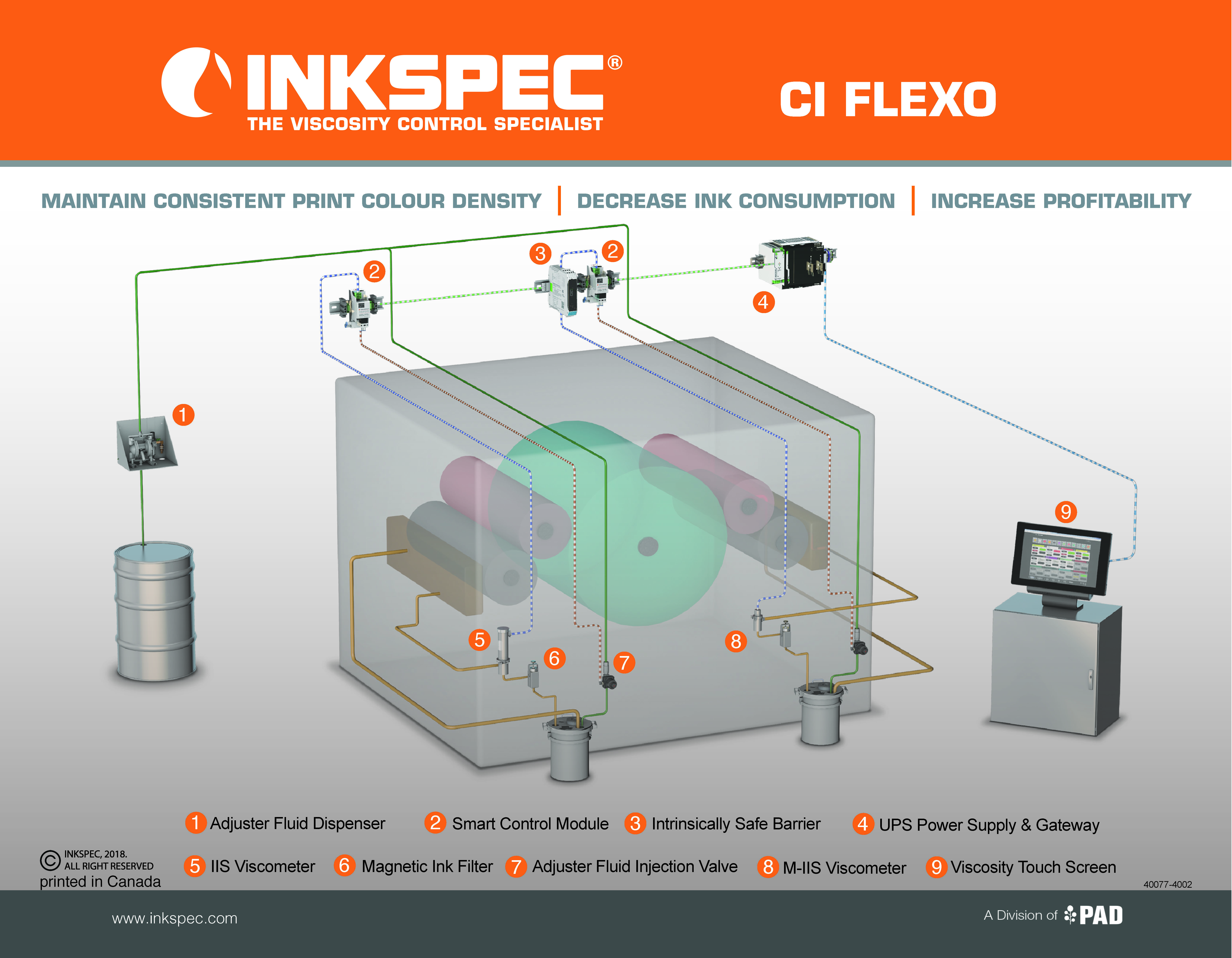

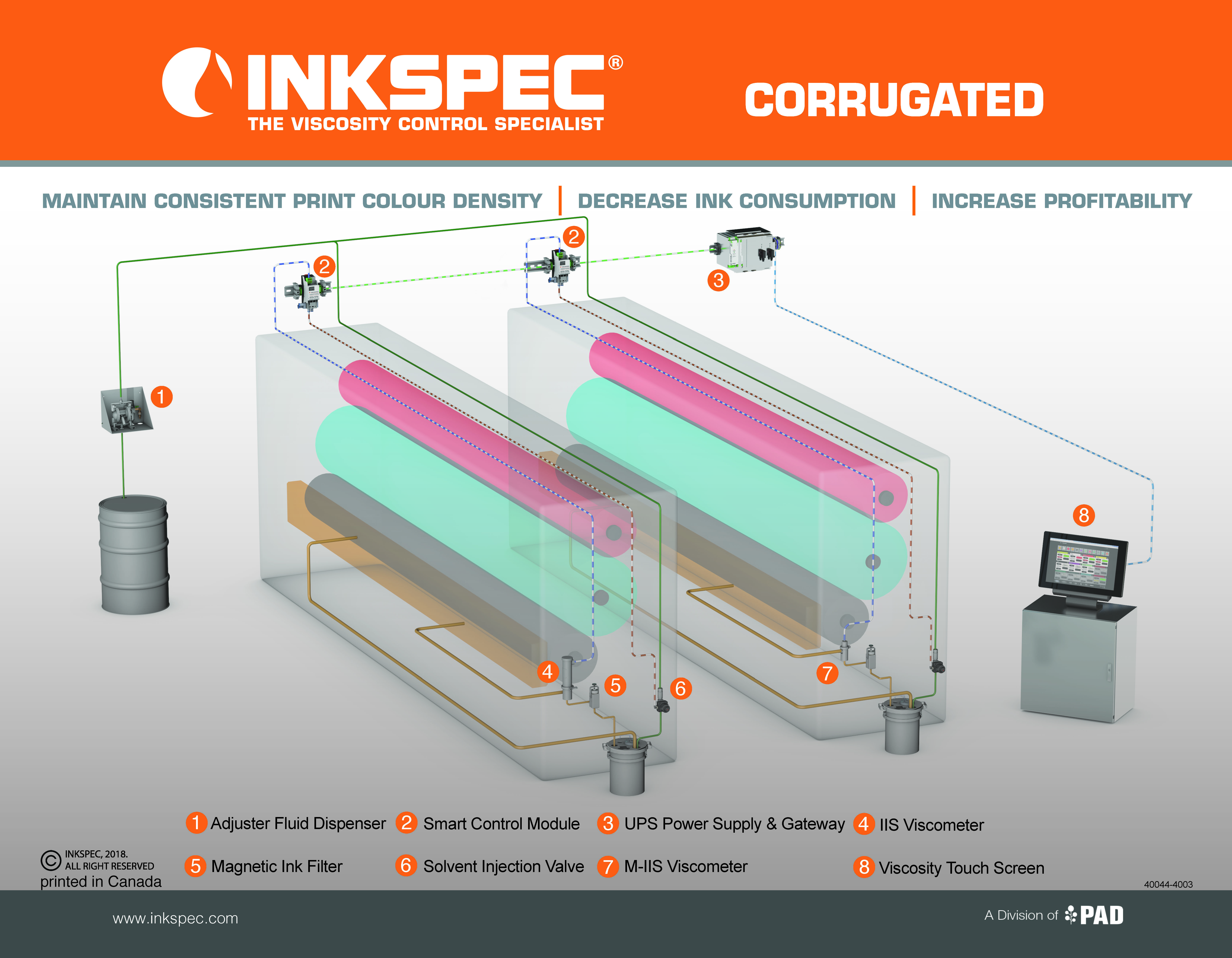

Corrugated Multi Station System

InkSpec Multi Station System on Corrugated Presses

Achieve unsurpassed control of your inking process with the InkSpec operating system, designed to meet the needs of press operators and the InkSpec smart system leads to major ink and time savings. Get real-time results that will increase the efficiency of any printing press. Generate tight viscosity control to maintain professional process quality.

Includes maintenance free viscometers with no moving parts! Easily set to the number of stations you want to control. The InkSpec Station Viscosity Control System includes:

- Adjuster Fluid Dispenser

- Adjuster Fluid Injection Valve

- Magnetic Filter

- Intelligent In-Line (IIS) Viscometer

- Touch Screen Monitoring Software

- Smart Control Module

Generate tight viscosity control to maintain professional process quality.

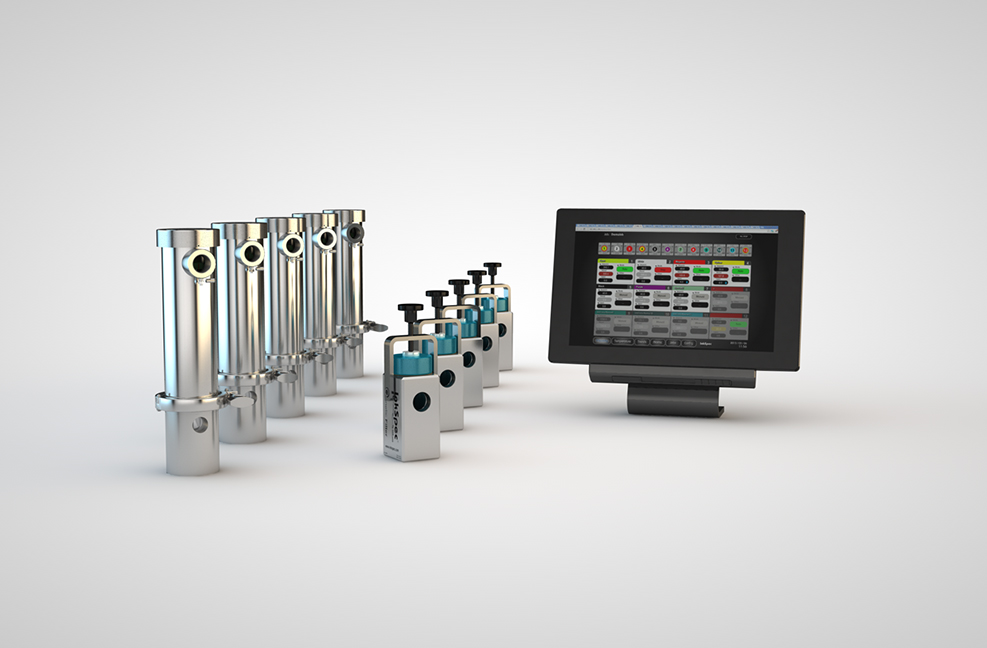

IIS Viscometer

Industry proven reliability for its innovative technology, the IIS (Intelligent In-line Sensor) has yet to determine its life cycle! The original viscometers, installed in 2004 are still in service and have not required any maintenance or service since!

The in-line installation provides real time, dynamic viscosity control and easy automatic wash-up. The process adapts to varying press conditions intuitively allowing the operator to adjust his process control to actual printing results.

- No moving parts… Maintenance free … The INKSPEC way!

- Providing absolute ink viscosity control to maintain print consistency and quality

- No spare parts inventory required

- No downtime for repair

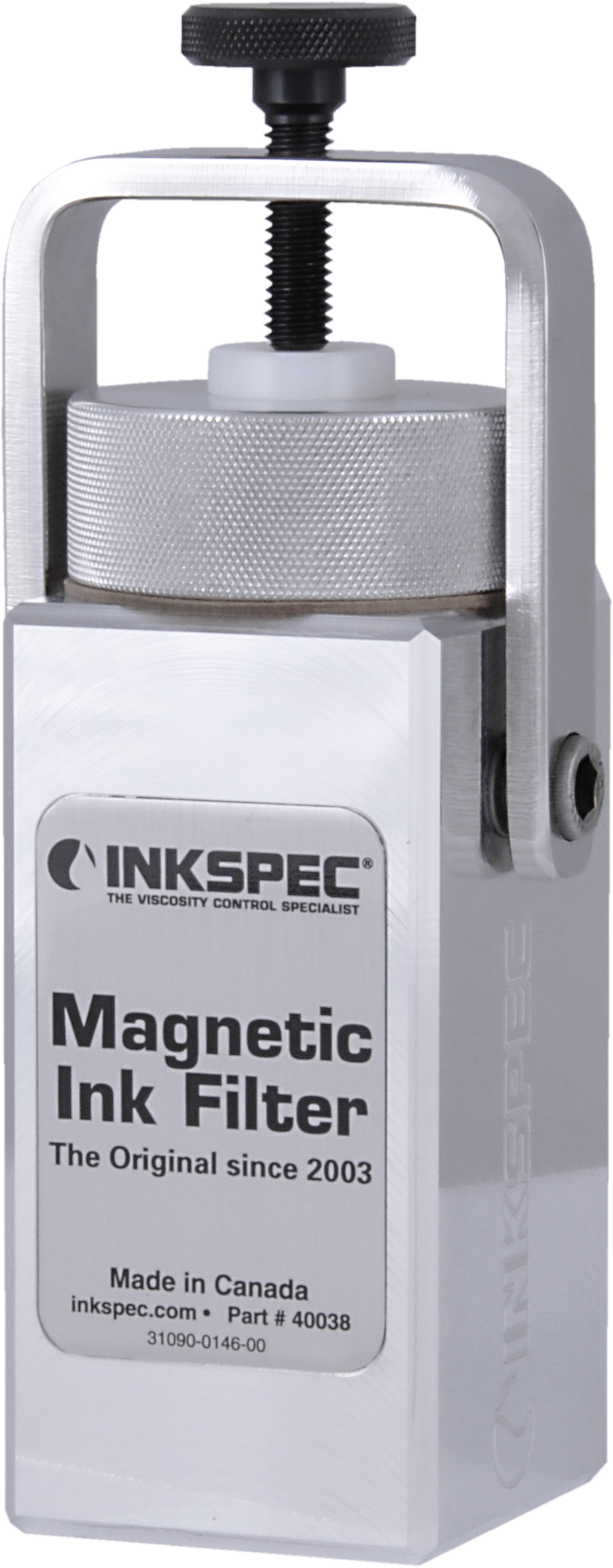

Magnetic Ink Filter

The InkSpec Magnetic Ink Filter increases printing efficiency while protecting anilox rolls and printing plates. Designed with rare earth magnets within a streamlined anodized aluminum shaft, it ensures turbulence free ink flow, eliminating ferrous metallic filaments and other contaminating particles.

- Fast cleaning on job changeovers, no tools required

- Reduces wear and tear

- Compact design for in-line Installation

- Can easily be placed on either side of the pumping circuit

Components:

Incorporating the great characteristics of the original IIS viscometer, the mIIS is a miniature version, with a smaller footprint that is easier to install in tight areas and adapts easily to manual or automatic wash-up systems. The in-line positioning enables the mIIS viscometer to adapt to varying press conditions intuitively, allowing the operator to relate his ink viscosity control to the actual printing results.

Available in two versions, one as an intrinsically safe version specifically for explosion-risk / hazardous areas, the other for water-based or “safe” applications.

Features:

- Inheriting the INKSPEC IIS viscometer’s award winning and proven reliable technology

- No moving parts… Maintenance free

- Providing absolute ink viscosity control to maintain print consistency and quality

- No spare parts inventory required

- No downtime for repair

The fluid dispenser is an integral part of the InkSpec Viscosity System. Its purpose is to supply the adjuster fluid, at a constant pressure, to ensure extremely accurate dosing and better ink control.

Features:

- Built with premium quality components

- Easy to Install

- Corrosion resistant painting

- Air muffler to reduce noise

Precise quantity, precise timing! The injection valve injects time-calculated amounts of the adjuster fluid into the ink pail to adjust the viscosity. The pressurized adjuster fluid (from the Adjuster Fluid Dispenser) is connected to the anti-syphon valve (also called check valve), and the output port is connected to a hose installed in the ink pail. Compact design, easy to install and compatible with corrosive liquids, various seal compositions available.

This smart software operates the Viscosity Control Process. The user-friendly ergonomic interface facilitates and standardizes the process. The software gets data from InkSpec’s reliable components to maintain the right viscosity level you selected. It will automatically control the viscosity to keep consistent printing and coating. Get at-a-glance dashboards for accurate decision making.

Features:

- Durable and Secure System

- Intuitive screen layout

- Pressure Control Alarm

- Real-time information

- Easy Installation; Custom InkSpec configuration and ready for service

* Available to specific countries; please consult with Goettsch International for availability.